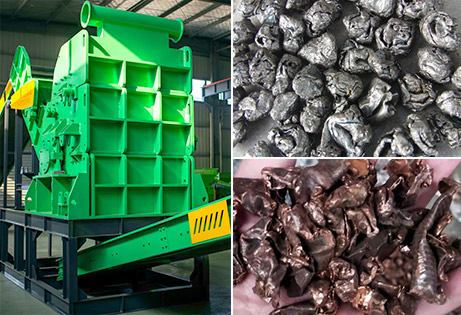

Metal Shredder / Hammer Mill Shredder

Input Size : Customize

Output Capacity : 200-10000kg/h

Applicable Material : Scrap metal, Scrap steel, Scrap iron, Scrap aluminum, Scrap radiator, Scrap copper, paint drums, diesel drums, thin iron sheets, car shells, metal briquettes, metal plate scraps etc.

Product Description

Metal Recycling Machine Can shred all kinds of scrap metal, scrap aluminum, scrap steel, scrap iron, scrap copper and other scrap metal materials. The metal shredder machine is mainly used for shredding scrap metal into small piece. The metal crusher machine is designed for a long service life energy efficiency and very low maintenance. The metal shredding machines can also be equipped with additional separating conveyor technology.

Scrap metal is one of the most valuable materials you can recycle, and it encompasses so many consumer products. From appliances to batteries to cans to clothes hangers, metal is everywhere in our homes. Recycling metal is important to not only keep this limited supply material out of landfills, but also because it can make you money.

Key equipment of metal crushing and recycling production line:

-

Metal Hammer Mill

-

Metal Shredder Machine

-

Metal Shearing Machine

-

Scrap Metal Shredder Sorting Line

Applicable materials:

√ Iron cuttings,sheet iron, sheet steel

√ Copper cuttings, sheet copper, Steel cuttings

√ Scrap iron bar, Waste steel wire

√ Waste wire, Waste steel pipe

√ Scrap metal, Scrap iron pipe

Metal crusher is suitable for crushing scrap steel, scrap iron, scrap aluminum and other metals. The metal crusher can be scientifically customized according to the crushed materials and processing capacity.

Metal Crushing Recycling Plant

-

Scrap Metal Shredder Sorting Line

-

Waste Aluminum Crushing Production Line

-

Water Radiator Crushing Sorting Line

-

UBC Aluminum Cans Decoating Machine

WORKING PRINCIPLE

Metal crusher hammer mill

Scrap metal crusher is the ideal solution for a wide range of ferrous and non ferrous metal applications in scrap yards and steel works. It is equipped with Hammer mill, a powerful motor, fully automatic electric control, hydraulic drive, sorting table, monitoring system,etc. ,Its widely used into iron ore ,scrap steel light metal scrap ,automobile body , bicycle , household appliance, metal barrel ,car body etc crushing ,rolling ,sorting purification ,ends to get 99.5% pure steel/iron with higher efficiency and big productivity the melting furnace to improve high metal using .

FEATURES

● Hydraulic adaptive feeding device.

● high strength impact crushing rotor.

● Automatic exclusion of non-breakable materials.

● super attack, swallow nesting ability, high production efficiency.

● high equipment operation rate, low maintenance cost.

● production process efficiency, low consumption, clean, high degree of automation Non-ferrous metals, steel, non-metallic automatic sorting recovery technology.

● multi-stage dust removal system, the production process clean working and environmentally friendly.

● Removing dust, paint and other impurities, to achieve "concentrate" into the furnace.

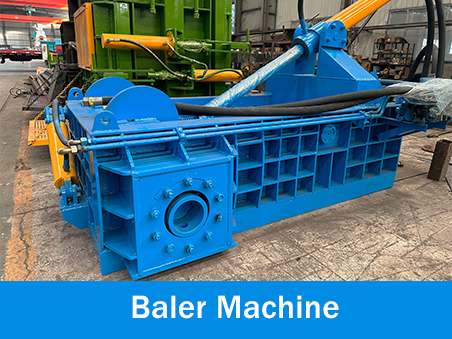

Other Metal Recycling Machine

Technical Parameters

| Model | Voltage | Powerkw) | Production capacity (t/h) | Configure auxiliary machine |

| PSJ-140 | 380V | 132 | 2-3 | 1 feeding conveyor

1 discharge conveyor 1 iron conveyor 1 impurity conveyor 1 magnetic separation system 1 dust removal system Intelligent visualization system (optional 1 set) Set of spray system (optional 1 set) |

| PSJ-200 | 380V | 200 | 3-5 | |

| PSJ-280 | 380V | 280 | 4-7 | |

| PSJ-315 | 380V | 315 | 5-8 | |

| PSJ-450 | 380V/10KV | 450 | 8-12 | |

| PSJ-630 | 10KV | 630 | 10-15 | |

| PSJ-750 | 10KV | 750 | 12-17 | |

| PSJ-800 | 10KV | 800 | 15-20 | |

| PSJ-900 | 10KV | 900 | 20-30 | |

| 1500horsepower | 10KV | 1200 | 25-40 | |

| 2000horsepower | 10KV | 1500 | 50-60 | |

| 3000horsepower | 10KV | 2250 | 60-80 | |

| 4000horsepower | 10KV | 3000 | 80-100 | |

| 6000horsepower | 10KV | 4420 | 100-160 | |

| 8000horsepower | 10KV | 6000 | 160-200 | |

| 10000horsepower | 10KV | 7500 | 200-260 |