Biomass Waste Shredder

Input Size : 200-2200mm

Output Capacity : 400-60000kg/h

Product Application : furniture factory ,wood recycling industry , wood tray factory , forest , fresh wood branch etc .

Applicable Material : Wood ,furniture factory side and corner materials, waste furniture, wooden trays, building templates, logs, branches, tree piers, tree roots

Product Description

Biomass appliance manufacturer of shredding, recycling and processing technologies for the production of alternative energy from waste and biomass, more than 10 years!

Having experiences in Wood, Coconut Husk, Maize Straw, Paddy Straw, Empty Fruit Bunch(EFB), Cotton Straw, Corn Stover and other organic materials used as alternative fuel, Xrido provides waste to energy solutions in Thailand, Malaysia, Vietnam, Korea, Japan, Poland, Italy, and Peru.

APPLICABLE

Wood pallet, Tree branch, Palm shells, Coconut shells, Straw

Wood ,furniture factory side and corner materials

waste furniture, wooden trays

Building templates, logs, branches, tree piers, tree roots

FINAL PRODUCT

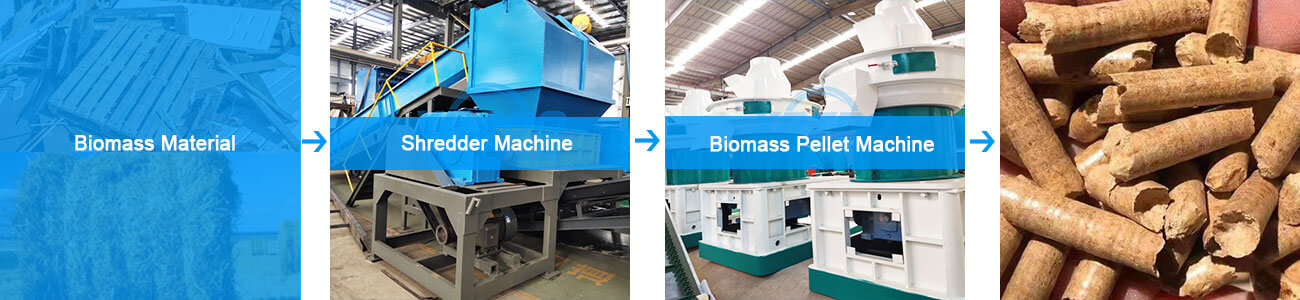

RDF Briquette Production Process:

Biomass Pellet Production Process:

XRIDO can provide the complete turnkey project biomass wood pellet production line, from design to install . Whether you want to produce wood pellet, sawdust pellet ,rice husk pellet, EFB pellet ,grass pellet or organic fertilizer pellet, the capacity is 1-100TPH can be choose.

WORKING PRINCIPLE

Wood shredder is driven by the independently double-roller.During the production the material will be pressed accordingly for automatic feed.During the production process of low speed and high torque,there is no spindle entanglement,or jammed equipment,thus improving the production efficiency,the equipment is suitable for Various materials of high toughness and viscosity.

FEATURES

1.The series of double-roller shaft with the characteristics of low speed ,large torque and low noise .Adopting the PLC control system for automatic control,with the function of start ,stop ,reversal and overload automatic reversal control

2.Motor and reducer drives the knife shaft then achieve the shear effect of low speed and high torque .

3.Bearing is equipped with six-weight seal, valid on the waterproof and dustproof, prolong the service life of the bearing.

4.After tool wear, tool welding repair technology is adopted to realize multiple reuse of the tool and greatly reduce the tool maintenance cost .

5.Designed with the split box ,conveniently remove the entire knife shaft (including shaft ,blades ,bearings and sealing system )

6.The tools are arranged according to spiral lines for efficient cutting.

7.The inner hole and main shaft surface are designed with the six-square then guarantee the uniformity of the tool force .

8.Different types of tools can be selected depending tearing different materials and product shapes.

Technical Parameters

| Model | Power (KW) | Rotating speed (r/min) | Dimensions L/W/H(mm) | Crushing cavity size C/D(mm) | Diameter of knife body (mm) |

| XR-56 | 15+15 | 6-20 | 2800×1300×1850 | 600×500 | 220 |

| XR-58 | 18.5+18.5 | 6-20 | 3000×1300×1850 | 800×500 | 220 |

| XR-710 | 30+30 | 6-20 | 3300×1900×2200 | 1000×700 | 320 |

| XR-812 | 37+37 | 6-20 | 3600×2000×2200 | 1200×800 | 400 |

| XR-815 | 45+45 | 6-20 | 4180×2100×2400 | 1500×850 | 450 |

| XR-918 | 75+75 | 6-20 | 5800×2400×3300 | 1800×900 | 500 |

| XR-1020 | 90+90 | 6-20 | 6400×2700×3500 | 2000×1000 | 600 |

| XR-1522 | 110+110 | 6-20 | 7800×3200×3800 | 2200×1500 | 800 |