Dust Removal System

High efficiency≥99.5%

Low leakage rate

Suitable bags and bag cages fitted according to dust properties. Glass Fiber, needle felt, PTFE, p84., etc

Product Description

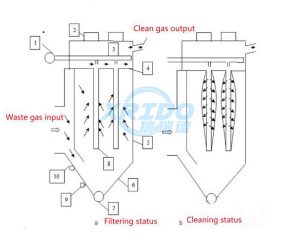

It combines the advantage of chamber blow and injection pulse soot cleaning of all kinds of bag filter, and overcomes the disadvantage of the chamber blow soot cleaning insufficient strength, and the injection pulse ash removal and filtering simultaneously, thus expands the application range of bag filter. Due to the structure has the characteristics of this type of filter, so it improves the efficiency of dust, prolong the service life of filter bag.

WORKING PRINCIPLE

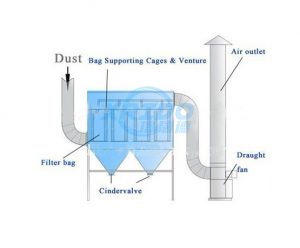

1. Under the action of the main draught fan, the dusty gas enter into the chamber through air inlet.

2. With the function of inertia and gravity, the coarser particles directly be discharged. Other light fine dust with air is adsorbed on the filter bag surface, the filtered clean gas will come through the filter bag into atmosphere finally.

FEATURES

1. High efficiency≥99.5%

2. Low emission concentration ≤20um, but also ≤10um is possible after filtering according to practical situation

3. Low leakage rate

4. Material—carbon steel or stainless steel

5. Simple Structure, easy maintenance

6. Suitable bags and bag cages fitted according to dust properties. Glass Fiber, needle felt, PTFE, p84., etc

7. The overhaul and bag replacement can be carried out for separate chamber under the condition that system blower and system run normally.

8. The whole set of equipment is controlled by PLC to realize automatic dust cleaning, dust removal, automatic temperature control and over temperature alarm

9. It is not sensitive to the characteristics of the dust, and it is not affected by dust and resistance.